NFK products are manufactured using an airtight system and our own custom machinery and equipment. We use cutting-edge bellows forming machines and braiding machines of the largest size classification, automatic welders to rapidly create solid welds, and leak testers and durability testers for checking product functionality and durability.

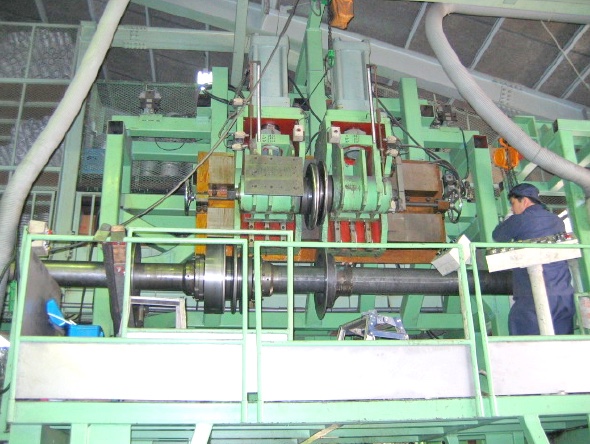

Bellows forming machines

-

2,000 mm diameter bellows forming machine

[Roll-type bellows forming machine]

Bellows are thin sheets of NFK stainless steel (0.2 to 3.0 mm thick) that have been rolled into cylinders (of 25 to 2,000 mm in diameter), then corrugated with a forming machine.

-

Bulge forming machine (up to 14B)

[Bulge-type forming machine]

Thin sheets of stainless steel (0.15 to 1.5 mm thick) are rolled into cylinders (of 17 to 350 mm in diameter), then corrugated with a bulge forming machine.

-

Spiral tube maker

[Roll-type one-pitch spiral forming machine]

Thin sheets of stainless steel (0.1 to 0.6 mm thick) are rolled into cylinders (of 3.5 to 65 mm in diameter), then corrugated with a roll forming machine.

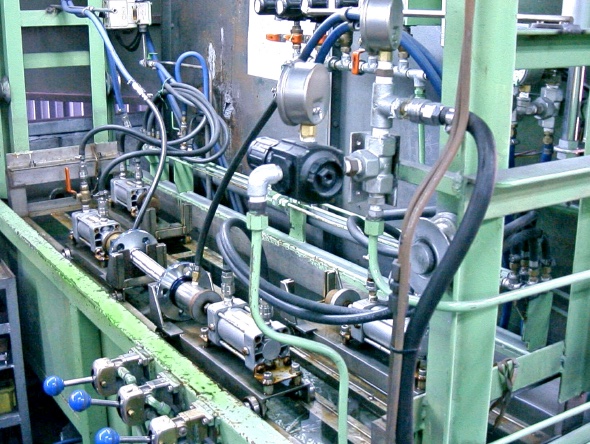

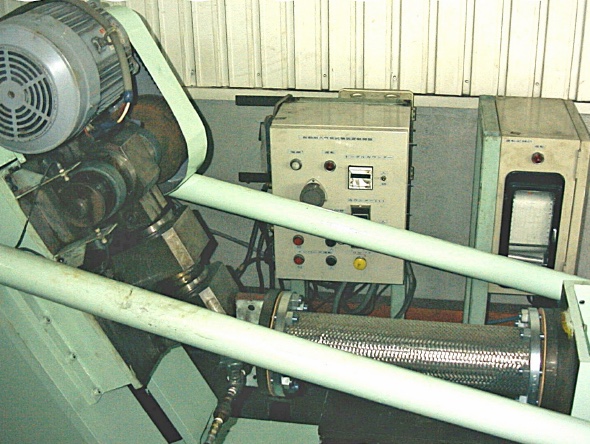

Braiding machine

-

Braiding machine of largest size class in Japan (14B)

A machine that manufactures wire braiding (stainless steel SUS304 wires of 0.3 to 0.6 mm in diameter) needed to provide pressure resistance to flexible tubes of 8 to 350 mm in diameter.

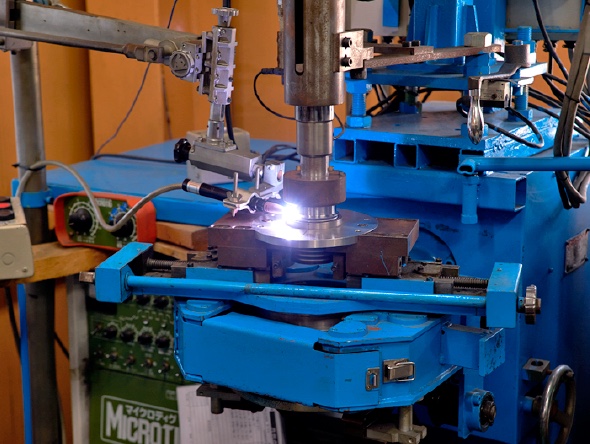

Welders

-

Fully automatic TIG welder

A 20 to 100 A fully automatic TIG welder for welding general-purpose flexible tubes.

-

Fully automatic precision welder

A fully automatic precision welder used exclusively for welding flexible tubes (semiconductor-related products made of thin sheets of 0.15 to 0.3 mm in thickness) for vacuum equipment and general vacuum lines.

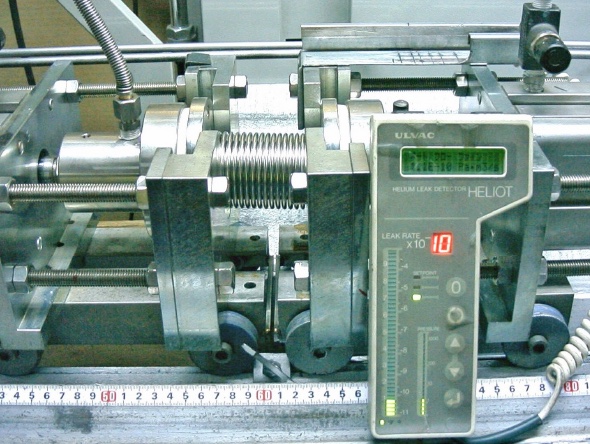

Pressure resistance/airtightness testers

-

Immersion-type airtightness tester

NFK uses an immersion-type airtightness tester to performs air leak tests on all products to prevent liquid leakage accidents.

-

Helium leak detector

[Helium leak tester]

A helium leak detector (high-sensitivity vacuum airtightness tester) for flexible tubes for semiconductor-related vacuum equipment and general vacuum lines. Permitted leak quantity: 1.33 × 10-10 Pa·m3/s

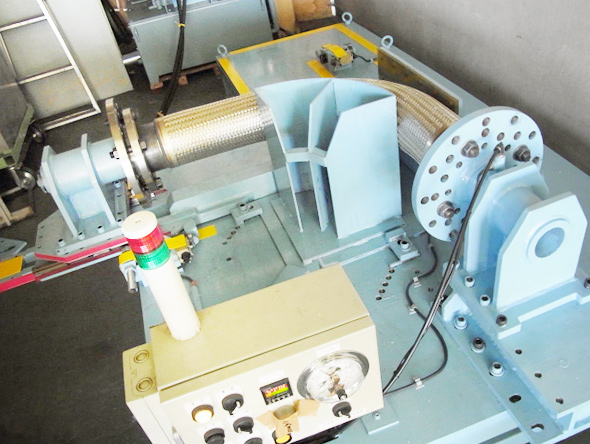

Durability testers

-

Repetitive displacement tester

[Displacement tester]

Tests durability by repeatedly displacing the specimen in the direction perpendicular to the axis while applying pressure.

-

Vibration tester

Tests flexible tube durability by applying vibrations of 1,000 cycles per minute with a total amplitude of 0.3 mm (axial direction) or 0.6 mm (direction perpendicular to axis).

-

Repetitive 90° bend tester

Repeatedly bends the specimen 90° as specified by ISO 10380.

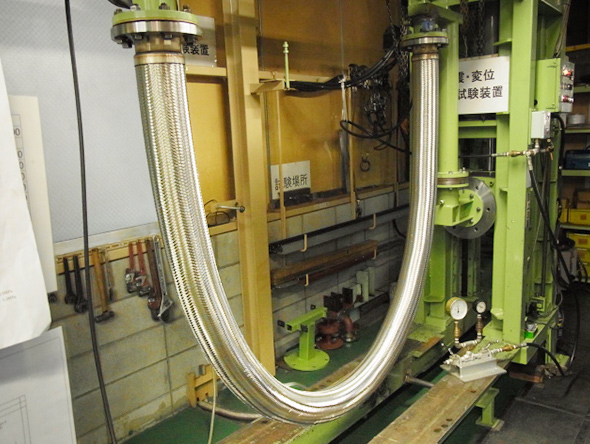

-

Repetitive U-bend tester

Repeatedly moves one side of the specimen up and down in a U shape as specified by ISO 10380.