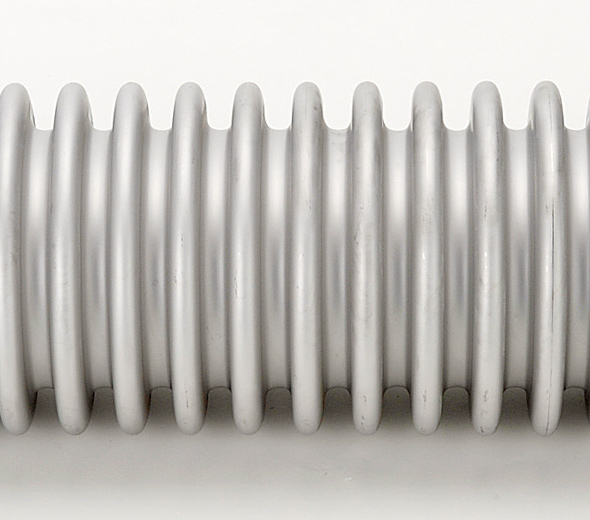

MF Bellows

Feature

A bellows are placed in a forming machine and individual or convolutions are formed by means of pressure exerted by forming wheels.

Material

SUS304 SUS316L SUS310S(100A~)

*Other special materials are also available.

Spec

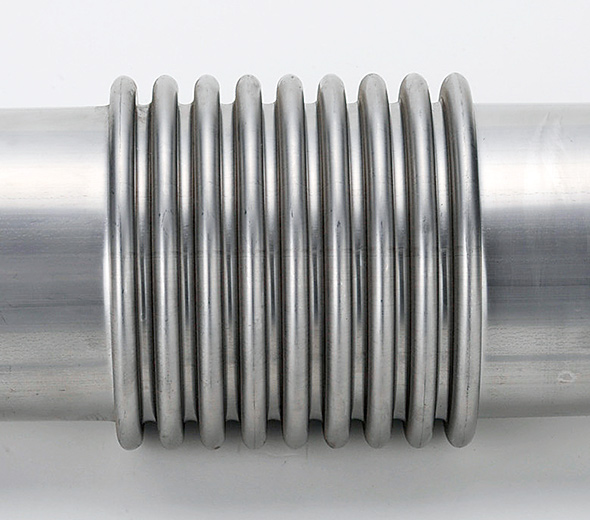

HF Bellows

Feature

A bellows are placed in hydraulic press or bellows forming machine.

High performance bellows of our best.

Material

SUS304 SUS316L SUS310S

*Other special materials are also available.

Spec

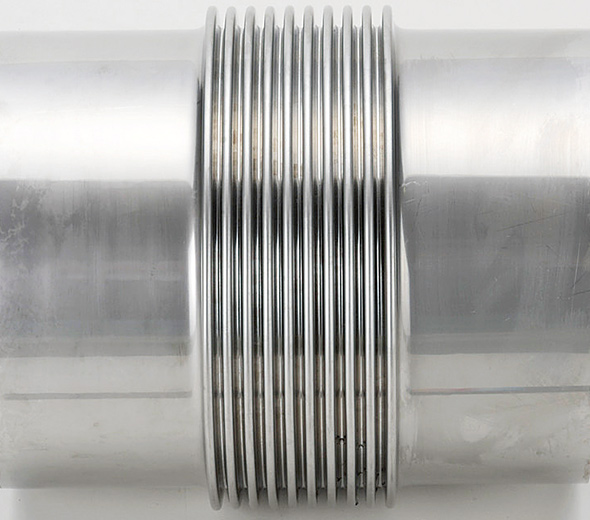

iO Bellows

Feature

From the inside of the pipe, by the technology of our own, is a bellows which is molded.

Material

SUS304 SUS316L SUS310S

*Other special materials are also available.

Spec

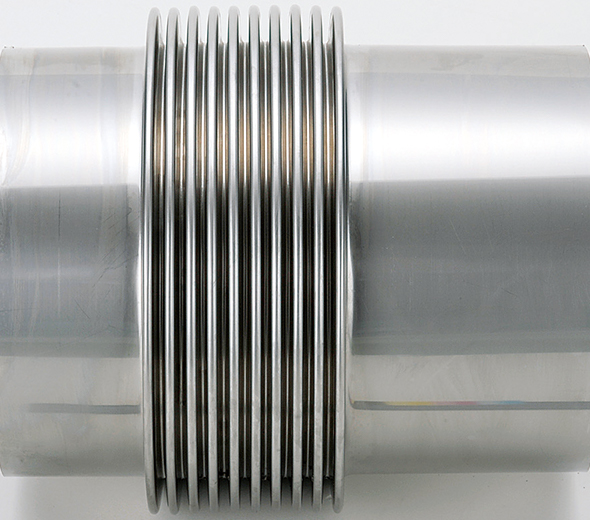

E Bellows

Feature

E-bellows are very soft and low reaction force.

Material

SUS304 SUS316L

*Other special materials are also available.

Spec

Aurora Bellows

Feature

Aurora bellows are phantasmagorias possible as more than 200 combined thicknesses, Peak Height, pitch.

Material

SUS304 SUS316L SUS310S

*Other special materials are also available.